Views: 0 Author: Site Editor Publish Time: 2025-10-29 Origin: Site

Have you ever wondered about the nuts holding your machinery together? Mechanical fastening plays a crucial role in various industries, ensuring safety and reliability.

In this article, we’ll explore slotted nuts and their function as locking mechanisms. You’ll learn whether a slotted nut can truly be considered a lock nut.

A slotted nut is a type of fastener designed to secure bolts and other components. It features distinct slots cut into its sides, allowing for easy installation and removal.

Typically, a slotted nut has a hexagonal shape, which helps it fit snugly against the bolt head. The slots are strategically placed, enabling the use of a cotter pin or wire to lock the nut in place.

● Shape: Hexagonal or round.

● Slots: Usually two or more, running parallel to the nut's axis.

● Dimensions: Common sizes range from 1/4 inch to 1 inch in diameter.

Here’s a simple illustration of a slotted nut:

_______

/ \

/ \

| ___ |

| | | |

\_________/

Slotted nuts come with several unique features:

● Number of Slots: Typically, they have two slots, but some may have more for added security.

● Alignment: The slots align precisely with the bolt holes for a secure fit.

While both slotted nuts and castellated nuts serve similar functions, there are key differences:

Feature | Slotted Nut | Castellated Nut |

Shape | Hexagonal or round | Typically hexagonal |

Slot Design | Straight slots | Notches or "castellations" |

Locking Mechanism | Cotter pin or wire | Cotter pin only |

Use Cases | General applications | Primarily in automotive settings |

The hexagonal corners of slotted nuts provide an excellent fit for cotter pins, ensuring they stay securely in place. This design enhances their reliability in high-vibration environments, making them ideal for various applications, from automotive to machinery.

Overall, slotted nuts are versatile and effective fasteners, playing a crucial role in mechanical assemblies.

A lock nut is a type of fastener designed to prevent loosening under vibration or torque. They play a crucial role in ensuring the stability of mechanical assemblies. Lock nuts are commonly used in various applications, from automotive to construction.

There are several types of lock nuts, each offering unique benefits:

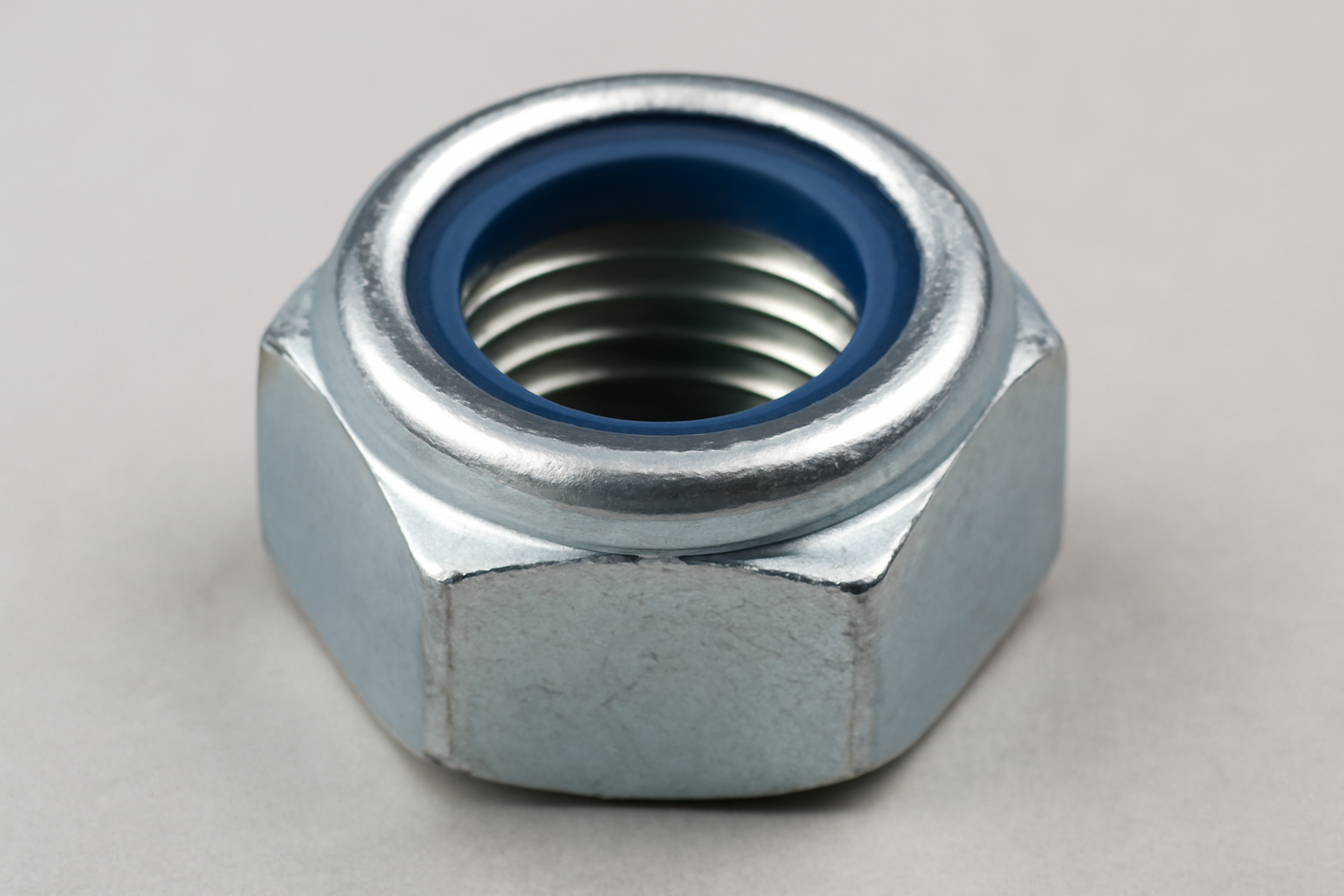

● Nylon-Insert Lock Nuts: These nuts feature a nylon collar that grips the bolt threads, providing friction to prevent loosening. They are easy to install and reusable.

● All-Metal Self-Locking Nuts: Made entirely of metal, these nuts deform slightly when tightened, creating a locking effect. They are suitable for high-temperature applications.

● Flange Nuts: These nuts have a wide flange that acts as a built-in washer. The flange distributes the load and helps resist loosening.

Here’s a quick comparison of these types:

Type | Material | Locking Mechanism | Reusability |

Nylon-Insert Lock Nut | Metal + Nylon | Friction from nylon | Yes |

All-Metal Self-Locking | All Metal | Deformation | Limited |

Flange Nut | Metal | Flange provides additional grip | Yes |

Lock nuts utilize various mechanisms to stay secure. Here’s a breakdown of the most common methods:

● Friction: In nylon-insert lock nuts, friction between the nylon insert and bolt threads prevents movement. This friction is crucial for maintaining tightness.

● Deformation: All-metal self-locking nuts rely on slight deformation. When tightened, they change shape, creating a tight grip on the bolt threads.

● Mechanical: Some lock nuts use mechanical features, such as serrations or grooves, to enhance grip. These designs help resist loosening due to vibrations.

Here’s a simple illustration to understand how these mechanisms work:

Nylon-Insert Lock Nut

______________________

| |

| [Nylon Insert] |

|______________________|

All-Metal Self-Locking Nut

______________________

| |

| [Deformed Shape] |

|______________________|Lock nuts are essential components in many mechanical systems. They ensure that connections remain secure, even in challenging environments. Understanding their types and how they work helps in selecting the right fastener for your needs.

When discussing slotted nuts, it's essential to compare them to traditional lock nuts. The primary difference lies in their locking mechanisms.

● Cotter Pin Method:

○ Slotted nuts utilize a cotter pin or wire inserted through the slots.

○ This creates a secure lock that prevents the nut from loosening.

● Friction-Based Methods:

○ Other lock nuts, like nylon-insert types, rely on friction to stay tight.

○ They grip the threads of the bolt, creating resistance to movement.

Here’s a quick comparison of these mechanisms:

Locking Mechanism | Slotted Nuts | Other Lock Nuts |

Method | Cotter pin or wire | Friction (nylon) |

Security Level | High (mechanical) | Moderate to High |

Reusability | Reusable, but may require new pins | Generally reusable |

● Slotted Nuts:

○ These can be reused if the cotter pin or wire is replaced.

○ Regular visual inspections are easy, allowing for quick checks of lock integrity.

● Other Lock Nuts:

○ Some friction-based lock nuts may lose effectiveness over time.

○ They might not be as easily inspected for wear.

Slotted nuts have several advantages when used as lock nuts:

● High Vibration Resistance:

○ They excel in high-vibration environments, maintaining tightness effectively.

● Reliability:

○ The mechanical locking method provides consistent performance.

One of the standout features of slotted nuts is the ease of visual inspection. You can quickly check if the cotter pin is in place, ensuring the lock is intact.

In extreme conditions, the mechanical security provided by slotted nuts outperforms friction-based methods. The cotter pin or wire mechanism ensures that even under significant stress, the nut remains securely fastened.

Here’s a visual representation of the advantages:

+-------------------------------------+

| Advantages of Slotted Nuts |

+-------------------------------------+

| 1. High Vibration Resistance |

| 2. Reliable Mechanical Security |

| 3. Easy Visual Inspection |

| 4. Reusable with New Cotter Pins |

+-------------------------------------+

Slotted nuts serve as effective locking mechanisms, especially in applications where reliability and safety are paramount. They provide unique benefits that make them a strong choice compared to other lock nuts.

Slotted nuts find widespread use across various industries due to their reliability and effectiveness. Here are some key sectors where they are commonly applied:

In the automotive industry, slotted nuts are crucial for several components:

● Wheel Hubs: They secure wheels to the vehicle, ensuring stability.

● Driveshafts: Slotted nuts help maintain the integrity of driveshaft connections.

● Suspension Systems: These nuts provide a secure fit for suspension components, enhancing safety and performance.

Heavy machinery also benefits from the use of slotted nuts:

● Cranes: They secure critical components, preventing failures during operation.

● Agricultural Equipment: Slotted nuts are used in tractors and harvesters, where reliability is essential.

In aerospace and rail applications, safety is paramount:

● Aerospace: Slotted nuts are used in aircraft assemblies, where vibration resistance is critical.

● Railway: They help secure track components and rolling stock, ensuring safe operation.

Here’s a summary table of applications:

Industry | Applications |

Automotive | Wheel hubs, driveshafts, suspension |

Heavy Machinery | Cranes, agricultural equipment |

Aerospace | Aircraft assemblies |

Railway | Track components, rolling stock |

Using slotted nuts in safety-critical applications is vital, especially in high-vibration environments. Here are some key points to consider:

● High Vibration Resistance: Slotted nuts provide superior resistance to loosening, making them ideal for applications where vibrations are common.

● Mechanical Locking: The cotter pin mechanism ensures a secure fit, minimizing the risk of failure.

● Regular Inspections: It’s essential to perform visual inspections to confirm that the cotter pin is intact. This helps maintain safety standards.

In applications where safety cannot be compromised, slotted nuts offer a dependable solution. Their unique design and locking mechanism make them suitable for various demanding environments, ensuring that components stay securely fastened.

When evaluating slotted nuts against other types of lock nuts, it's essential to understand their distinct characteristics. Below is a comparison table that highlights the key differences among slotted nuts, nylon-insert lock nuts, all-metal self-locking nuts, and flange nuts.

Type of Nut | Locking Mechanism | Vibration Resistance | Reusability | Visual Inspection | Cost |

Slotted Nut | Cotter pin or wire | High | High | Easy | Moderate |

Nylon-Insert Lock Nut | Friction (nylon insert) | Moderate | Moderate | Difficult | Low |

All-Metal Self-Locking Nut | Thread deformation | High | Low | Moderate | High |

Flange Nut | Integrated washer | Moderate | Moderate | Moderate | Moderate |

Pros:

● Visible Security: The cotter pin provides a clear indication of whether the nut is secure.

● High Reusability: They can be reused multiple times, making them cost-effective in the long run.

● Excellent Vibration Resistance: Ideal for applications with significant vibration, ensuring components remain tight.

Cons:

● Requires Additional Hardware: The need for a cotter pin or wire can be seen as an extra step during installation.

Pros:

● Cost-Effective: Generally cheaper than slotted and self-locking nuts.

● Easy to Install: Simple design allows for quick installation.

Cons:

● Limited Reusability: The nylon insert can wear out after several uses, reducing effectiveness.

● Moderate Vibration Resistance: Not as effective in high-vibration environments.

Pros:

● High Vibration Resistance: Excellent for extreme conditions where other nuts may fail.

● No Additional Hardware Needed: Simplifies the assembly process.

Cons:

● Low Reusability: Once used, they often cannot be reused effectively.

● Potential for Thread Damage: May cause wear on the bolt threads during installation.

Pros:

● Integrated Washer: Reduces the chance of loosening due to vibration.

● Moderate Cost: Balances performance and expense effectively.

Cons:

● Limited Locking Mechanism: May not be as secure as slotted nuts in high-stress applications.

● Moderate Reusability: Similar to nylon-insert nuts, they can wear out over time.

In conclusion, while each type of lock nut has its own advantages and disadvantages, slotted nuts stand out for their unique benefits, such as visible security and high reusability. This makes them a preferred choice in many applications where safety and reliability are crucial.

When selecting slotted nuts, adhering to industry standards is crucial. Several relevant standards ensure quality and reliability:

● DIN 935: This German standard specifies dimensions and tolerances for slotted nuts, ensuring compatibility across various applications.

● ASTM A563: An American standard that covers the requirements for carbon and alloy steel nuts, including slotted variations.

These standards help manufacturers produce slotted nuts that meet safety and performance expectations. Compliance with such standards guarantees that the nuts can withstand the demands of different environments.

Slotted nuts offer significant cost advantages compared to specialty lock nuts. Here’s a quick look at their cost-effectiveness:

Type of Nut | Average Cost (per 100 units) | Reusability | Customization Options |

Slotted Nut | Moderate | High | Sizes, finishes |

Specialty Lock Nut | Higher | Low | Limited |

One of the standout features of slotted nuts is their versatility. They can be customized in various ways:

● Sizes: Available in multiple diameters and thread pitches to fit different applications.

● Finishes: Options include zinc plating, black oxide, and other coatings for corrosion resistance.

● Variants: Slotted nuts come in hex, round, and heavy-duty styles, catering to specific needs.

Here’s a brief overview of common customization options:

Customization Type | Description |

Hex Nuts | Standard shape for easy handling |

Round Nuts | Smooth edges, aesthetic appeal |

Heavy-Duty Variants | Designed for high-stress applications |

By choosing slotted nuts, you gain not only cost savings but also flexibility in meeting your project requirements. Their adaptability makes them a practical choice for a wide range of applications.

In summary, slotted nuts are indeed a type of lock nut. They provide visible security and high reusability. Choosing the right nut is crucial for your application. Proper selection ensures safety and performance.

Explore DIN 935-compliant slotted nuts for reliable mechanical fastening solutions. Their versatility and cost-effectiveness make them an excellent choice for various projects.

A: Yes, slotted nuts are highly reusable, making them cost-effective.

A: They are typically made from steel, stainless steel, or other durable materials.

A: Install by threading it onto a bolt and securing it with a cotter pin.

A: Avoid over-tightening and ensure proper alignment during installation.

A: High-quality slotted nuts can be purchased from hardware stores or specialized suppliers.

A: Slotted nuts maintain performance in extreme temperatures, depending on the material used.