Have you ever struggled with securing components in your projects? T-slot nuts are essential for reliable fastening in various applications. Understanding how to use these fasteners effectively is crucial for optimal machine tool fixturing. In this post, you’ll learn how T-slot nuts and slotted nuts work together to enhance your projects.

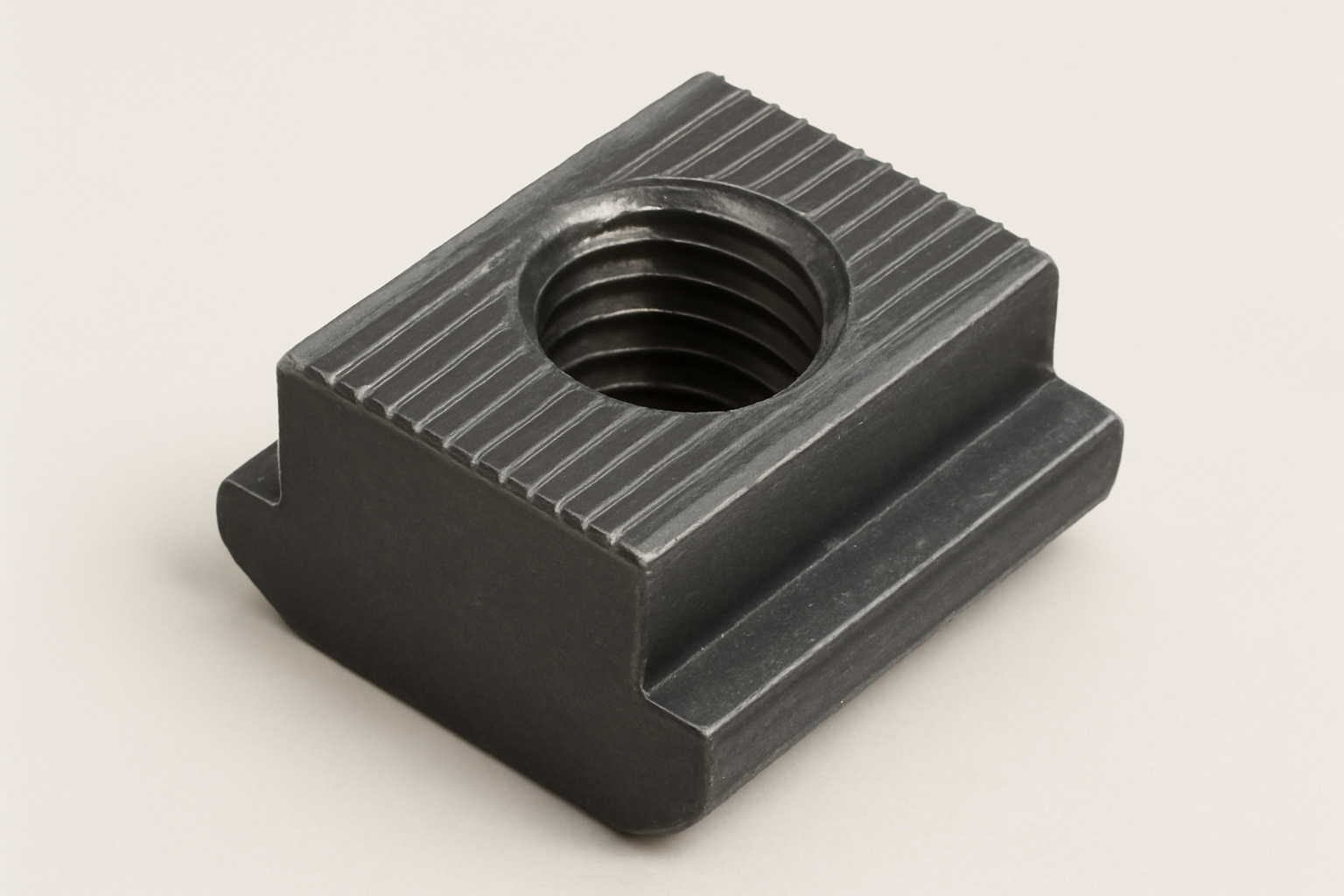

T-slot nuts are specialized fasteners designed to fit into T-slots on machinery and equipment. Their unique shape allows for versatile positioning and secure fastening. They are essential in various applications where stability and flexibility are required.

The T-shaped profile of these nuts is what sets them apart. This design allows the nut to slide into the T-slot, providing a secure grip. Once positioned, you can tighten a bolt into the nut, which locks everything in place.

Key Features:

● Versatility: Easily adjustable for different setups.

● Stability: Provides a strong hold under stress.

● Ease of Use: Simple to install and remove.

T-slot nuts are widely used in several industries. Here are some common applications:

● Milling Machines: They secure workpieces, ensuring precision during machining.

● Lathes: Used to hold fixtures in place for turning operations.

● 3D Printers: Essential for mounting components and ensuring stability during printing.

● Industrial Framing: Frequently found in modular framing systems, allowing for flexible layouts.

When comparing T-slot nuts to other fastening solutions, several unique features stand out.

Feature | T-Slot Nuts | Standard Nuts |

Adjustability | High; can be repositioned easily | Low; fixed once tightened |

Installation Ease | Quick; no special tools needed | Moderate; may require specific tools |

Load Distribution | Even; distributes weight effectively | Variable; may concentrate stress |

T-slot nuts offer greater flexibility and ease of use compared to traditional fastening methods. Their design allows for quick adjustments, making them ideal for dynamic applications. This adaptability is crucial in settings where modifications are frequent.

T slot nuts are essential components in various machining and construction applications. Their unique T-shaped profile allows them to fit snugly into T-slots on work tables, providing a secure anchoring point for fixtures and other attachments. This design enables easy adjustment and repositioning of components, making it a favorite among machinists and DIY enthusiasts alike.

● T-shaped profile: Ensures a tight fit in T-slots.

● Versatile: Compatible with various fixtures and tools.

● Adjustable: Allows for easy repositioning without removing the entire assembly.

T slot nuts are typically made from durable materials to withstand the rigors of machining and assembly. Common materials include:

● Carbon Steel: Offers strength and durability, often used in general applications.

● Stainless Steel: Provides corrosion resistance, ideal for environments exposed to moisture or chemicals.

These materials ensure that T slot nuts maintain their integrity under pressure and resist wear over time.

T slot nuts come in various sizes to accommodate different applications. Here are some standard sizes you might encounter:

Size | Thread Type |

M4 | Metric |

M5 | Metric |

M6 | Metric |

M8 | Metric |

M10 | Metric |

M12 | Metric |

M16 | Metric |

M20 | Metric |

These sizes ensure compatibility with various bolts and fixtures, allowing for flexibility in design and assembly.

T slot nuts work best when paired with complementary components that enhance their functionality.

Slotted nuts are often used alongside T slot nuts to provide additional security. Their design features slots that allow for the insertion of a locking mechanism, such as a cotter pin. This setup helps prevent loosening due to vibration or movement, making it particularly useful in high-stress applications.

Cotter pins play a crucial role in securing connections between T slot nuts and slotted nuts. They fit through the slots in the nuts, locking everything in place. This simple yet effective mechanism ensures that components remain securely fastened, even under heavy loads.

When selecting slotted nuts, it's vital to consider their specifications. Common standards include:

● DIN 935: This standard outlines the dimensions and tolerances for slotted nuts, ensuring uniformity across different manufacturers.

● ISO 4032: Similar to DIN 935, this standard provides guidelines for the design and dimensions of slotted nuts, promoting compatibility in international applications.

These specifications help ensure that you select the right components for your assembly, enhancing overall reliability and performance.

By understanding the components of T slot nuts, you can make informed decisions about their use in various applications. Whether you're a seasoned machinist or a DIY enthusiast, knowing the ins and outs of these essential fasteners can significantly impact your projects.

Before diving into the installation process, it's essential to gather the necessary tools and follow safety precautions.

To successfully install T slot nuts, you'll need a few key tools:

● Wrench: For tightening bolts.

● Cotter Pins: To secure slotted nuts.

● Screwdriver: For adjustments.

● Torque Wrench: To ensure proper tightness.

● Measuring Tape: For accurate alignment.

Having these tools ready will make the process smoother and more efficient.

Safety should always come first. Here are some important precautions to keep in mind:

● Wear Safety Gear: Use gloves and goggles to protect yourself from sharp edges and flying debris.

● Work in a Well-Lit Area: Good lighting helps prevent accidents.

● Keep Your Workspace Organized: A clutter-free area reduces the risk of tripping or misplacing tools.

Common Hazards to Avoid:

● Loose clothing that can get caught in machinery.

● Using damaged tools, which can lead to injuries.

Now, let's move on to the actual installation of T slot nuts.

Follow these steps to insert a T slot nut properly:

1. Identify the T-slot: Locate the T-slot on your work surface.

2. Align the Nut: Position the T slot nut at the opening of the T-slot.

3. Insert the Nut: Slide the nut into the slot until it sits flush against the bottom.

● Ensure the flange of the nut is level with the surface.

● Use a flashlight to check for gaps between the nut and the T-slot.

While inserting T slot nuts, keep an eye out for these common errors:

● Misalignment Issues: If the nut isn’t aligned properly, it can lead to instability.

● Incorrect Nut Orientation: Always ensure the flange is facing the right direction.

● Incomplete Bottom Thread: This prevents the bolt from rotating freely, which can cause issues during tightening.

Once the T slot nut is in place, it’s time to align your workpiece and insert the bolt.

Proper alignment is crucial for a successful assembly. Here are some techniques:

● Use a Measuring Tape: Measure distances from fixed points to ensure everything is centered.

● Visual Checks: Step back and visually inspect the alignment.

Now, let’s insert the bolt:

1. Select the Right Bolt: Ensure compatibility with the T slot nut.

2. Insert the Bolt: Slide it through the workpiece and into the T slot nut.

3. Tighten the Bolt: Use a wrench to secure it in place.

Always check that the bolt thread matches the T slot nut. This ensures a secure fit and prevents stripping.

Notes on Heavy-Duty Applications: For heavy-duty setups, consider using DIN 934 heavy hex slotted nuts for added strength.

After inserting the bolt, it’s time to tighten and secure everything.

To properly tighten the slotted nut, follow these steps:

1. Use a Torque Wrench: This helps achieve the correct tightness.

2. Follow Recommended Torque Specifications: For example, M10 should be tightened to 15–20 N·m for steel applications.

Utilizing cotter pins effectively is crucial for securing connections:

● Insert the Cotter Pin: Place it through the slot in the nut.

● Bend the Ends: This locks the nut in place, preventing it from loosening.

Advantages of Broader Pin Engagement: Using a cotter pin with broader engagement enhances stability and reduces the risk of disconnection during operation.

After everything is installed, fine-tuning is essential.

If adjustments are needed, here’s how to do it:

● Loosen the Bolt Slightly: This allows for repositioning.

● Realign as Necessary: Use measuring techniques to ensure accuracy.

Testing is vital, especially in high-vibration environments:

● Importance of Testing: It ensures that all components remain secure during operation.

● Recommended Types of Slotted Nuts: For high-vibration setups, consider using DIN 6923 serrated flange slotted nuts. These provide extra grip and stability.

By following these steps, you can effectively use T slot nuts in your projects. Each stage is crucial for ensuring a secure and reliable assembly.

When using T slot nuts, understanding their specifications is crucial for ensuring compatibility with your projects. Here’s a detailed look at the key specifications you should consider.

T slot nuts come in various specifications that dictate their use and performance.

Several standards govern the design and manufacturing of T slot nuts, including:

● TC MAI: This standard focuses on the dimensions and tolerances specific to T slot nuts.

● DIN: The German Institute for Standardization provides guidelines to ensure uniformity across manufacturers.

T slot nuts are available in a range of sizes to fit different applications. Here are some of the most common sizes:

Size | Thread Type | Surface Finish |

M4 | Metric | Black Oxide |

M5 | Metric | Galvanized |

M6 | Metric | Zinc Plated |

M8 | Metric | Plain |

M10 | Metric | Anodized |

Surface Finishes: These finishes enhance corrosion resistance and durability. For example, black oxide offers a sleek appearance and minimal corrosion, while galvanized finishes provide extra protection against rust.

Slotted nuts are often used in conjunction with T slot nuts for added security.

The specifications for slotted nuts are also defined by several standards:

● DIN 935: This standard outlines the dimensions and tolerances for slotted nuts.

● ISO 4032: Similar to DIN 935, it provides guidelines for slotted nut design, ensuring international compatibility.

Slotted nuts are available in various materials and sizes, catering to different applications. Here’s a quick overview:

Material | Common Sizes |

Carbon Steel | M6 to M48 |

Stainless Steel | M6 to M48 |

Brass | M6 to M36 |

Material Options: Choosing the right material is essential. Carbon steel is strong and cost-effective, while stainless steel offers excellent corrosion resistance. Brass is suitable for lighter applications.

By understanding these specifications, you can select the right T slot nuts and slotted nuts for your projects, ensuring a secure and reliable assembly.

T slot nuts are versatile components used in various applications across different industries. Their unique design allows for easy installation and secure fastening. Here’s a closer look at how they are applied in machining, automotive, and DIY fabrication projects.

T slot nuts are essential in machining environments, especially in CNC machining and milling.

● Secure Workpieces: T slot nuts hold workpieces firmly in place during machining processes.

● Easy Adjustments: They allow for quick repositioning of components, which is vital for precision work.

In milling operations, jigs need to be secured effectively. Here’s how T slot nuts help:

● Versatility: They fit into T slots on milling tables, providing a stable base for jigs.

● Customizable Setup: Users can easily adjust the position of jigs as needed.

In the automotive industry, T slot nuts play a critical role in various components.

● Sturdy Connections: T slot nuts are used in suspension linkages, ensuring reliable connections under stress.

● Safety: Their strength is crucial for maintaining vehicle stability.

Using T slot nuts instead of adhesives like Loctite offers several benefits:

● Reusability: T slot nuts can be easily removed and reused, unlike adhesives.

● Strength: They provide a stronger connection in high-stress environments, reducing the risk of failure.

T slot nuts are also popular in DIY projects, making them a favorite among hobbyists and makers.

Here are some creative projects where T slot nuts can be utilized:

Project Type | Description |

Outdoor Frames for Solar Mounts | Create adjustable frames for solar panels. |

Modular Workbenches | Build customizable and expandable workspaces. |

Camera Rigs | Design stable platforms for photography. |

Benefits for DIY Enthusiasts:

● Flexibility: Easy to modify and adapt designs.

● Stability: Ensures strong connections that last.

T slot nuts truly enhance the functionality and versatility of various applications, whether in industrial settings or personal projects.

To maximize the effectiveness of T slot nuts, following best practices is essential. These practices ensure secure fastening, prevent mistakes, and maintain the integrity of your projects. Let’s dive into the optimal techniques, common pitfalls, and maintenance tips.

When using T slot nuts, employing the right techniques can make a significant difference in performance.

● Machining: Use T slot nuts to secure workpieces tightly on CNC machines. This prevents movement during cutting.

● Automotive: For suspension linkages, ensure a snug fit to withstand vibrations and stresses.

● DIY Projects: In projects like modular furniture, adjust the nuts to allow for future modifications.

Even experienced users can make errors when using T slot nuts. Here are some common mistakes to avoid:

● Over-tightening: Applying too much torque can strip threads or damage components. Always use a torque wrench to apply the correct force.

● Thread Pitch Mismatches: Ensure the thread pitch of the bolt matches the T slot nut. Mismatched threads can lead to weak connections and failure.

Regular maintenance helps prolong the life of T slot nuts and ensures they function correctly.

● Inspect Regularly: Check for signs of wear, corrosion, or damage. Replace any nuts that show significant wear.

● Keep it Clean: Dirt and debris can affect the performance. Clean the nuts and slots regularly to maintain smooth operation.

When working with metric systems, matching thread pitch is crucial. Here’s why:

Thread Size | Common Pitch (mm) | Importance |

M6 | 1.0 | Ensures a secure fit |

M8 | 1.25 | Prevents cross-threading |

M10 | 1.5 | Maintains strength under stress |

Using the correct thread pitch helps avoid issues like loosening over time, ensuring your assembly remains secure.

By following these best practices, you can effectively use T slot nuts in various applications, enhancing both safety and performance.

T slot nuts are crucial components in various applications. They provide secure fastening, making them ideal for machining, automotive, and DIY projects.

Following best practices ensures effective use. Always check for thread pitch and avoid over-tightening.

We encourage you to experiment with T slot nuts in your projects. Discover their versatility and enhance your designs!

A: T slot nuts provide easy installation, secure fastening, and versatility across various applications.

A: Yes, T slot nuts can be easily removed and reused without losing their effectiveness.

A: Match the nut size with the bolt diameter and ensure compatibility with your T slot dimensions.

A: Stainless steel is ideal for corrosive environments, while aluminum suits lightweight applications.

A: Alternatives include standard hex nuts and locknuts, but they lack the same versatility in T slots.

A: T slot nuts offer easier adjustments and secure mounting in T slots, unlike standard nuts.