Have you ever wondered how machinery stays securely assembled? T-slot nuts play a crucial role in various industrial applications, ensuring stability and precision. In this article, we’ll explore what a T-slot nut is, its importance, and how it compares to slotted nuts.

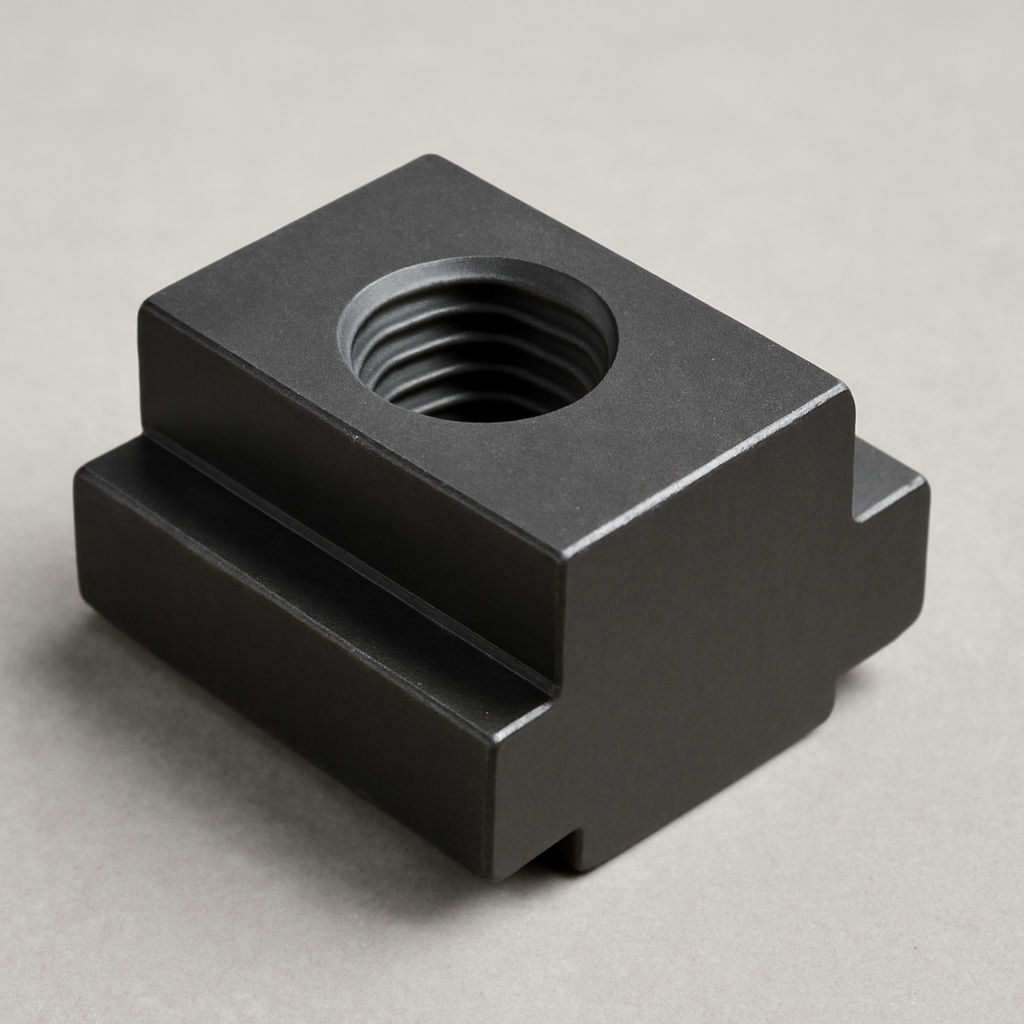

So, what exactly is a T-slot nut? It's a specialized fastener designed to fit into T-slots, commonly found in framing systems. The unique T-shaped profile allows it to slide along the slot and lock securely in place. This design is essential for creating adjustable and modular structures, making it a favorite in various industries.

Functionality of the T-Shaped Profile:

● Sliding Mechanism: Easily slides into the T-slot.

● Secure Locking: Once in position, it prevents movement.

● Versatility: Works well with different types of bolts and screws.

T-slot nuts come in various materials and specifications, ensuring they meet the demands of different applications. Here are some key options:

● Carbon Steel: Strong and cost-effective, ideal for general use.

● Stainless Steel: Corrosion-resistant, perfect for outdoor or humid environments.

● Alloy Steel: Offers enhanced strength for heavy-duty applications.

T-slot nuts are available in common metric sizes, including:

● M4

● M5

● M6

● M8

● M10

The finish of a T-slot nut can affect its durability and appearance. Common finishes include:

● Zinc Plating: Provides basic corrosion resistance.

● Black Oxide: Offers a sleek look and moderate protection.

● Passivation: Enhances corrosion resistance, especially for stainless steel.

One notable aspect of T-slot nuts is their incomplete threads on the base. This design helps prevent stud slippage, ensuring a secure fit during use.

Here's a quick overview of the specifications:

Feature | Options |

Materials | Carbon Steel, Stainless Steel, Alloy Steel |

Thread Sizes | M4, M5, M6, M8, M10 |

Surface Finishes | Zinc Plating, Black Oxide, Passivation |

Design Features | Incomplete threads for stability |

T-slot nuts are essential components in many industrial and DIY projects. Their design and features make them reliable and versatile tools for various fastening needs.

Ever wondered how T-slot nuts lock securely into place? The secret lies in their unique design. When you slide a T-slot nut into the T-slot of a frame, it fits snugly. Once positioned, tightening a bolt or screw draws the nut against the side of the slot. This action creates a strong grip, preventing any movement.

Key Steps in the Locking Process:

1. Insertion: Slide the T-slot nut into the slot.

2. Positioning: Move it to the desired location.

3. Tightening: Use a bolt or screw to secure it firmly.

The bolts and screws play a crucial role here. They not only hold the T-slot nut in place but also provide the necessary pressure to keep everything stable.

Now, let’s compare T-slot nuts to slotted nuts. While both serve as fastening solutions, they have distinct differences.

● Design:

○ T-Slot Nuts: Feature a T-shaped profile for sliding into slots.

○ Slotted Nuts: Have a simple, flat design with slots for a wrench.

● Functionality:

○ T-Slot Nuts: Ideal for adjustable frameworks.

○ Slotted Nuts: Better for fixed applications.

● T-Slot Nuts: Use these when you need flexibility and adjustability, like in modular setups or machinery that requires frequent adjustments.

● Slotted Nuts: Opt for slotted nuts in situations where vibration is minimal and a secure, static connection is required.

Example Uses:

● T-Slot Nuts: Excellent for rigid mounting in CNC machines where adjustments are needed.

● Slotted Nuts: Preferable in applications like automotive assemblies where components are fixed and less prone to movement.

Here’s a quick comparison table for clarity:

Feature | T-Slot Nuts | Slotted Nuts |

Design | T-shaped profile | Flat design with slots |

Best Use | Adjustable frameworks | Fixed applications |

Example | CNC machine mounts | Automotive assemblies |

Understanding how T-slot nuts work and how they differ from slotted nuts will help you choose the right fastener for your project. They each have their strengths, making them suitable for different applications.

T-slot nuts are essential in various industries, playing a crucial role in machining, woodworking, and automation. Their versatility makes them a go-to choice for many applications.

Common Applications Include:

● Machining: Used in milling machines to secure workpieces and fixtures.

● Woodworking: Ideal for assembling jigs and fixtures in woodworking projects.

● Automation: Frequently found in conveyor systems and robotic arms for adjustable setups.

Examples of Machinery and Equipment Utilizing T-Slot Nuts:

● Milling Machines: T-slot nuts secure the table and tool holders, ensuring precision during operations.

● 3D Printers: They help in mounting components and adjusting the printer frame.

● CNC Machines: Essential for holding workpieces firmly in place during complex machining tasks.

One of the standout features of T-slot nuts is their ability to facilitate adjustable and modular setups. This makes them incredibly useful in both commercial and DIY projects.

Benefits in Modular Framing:

● Flexibility: Easily reposition components as needed.

● Customization: Tailor builds to specific requirements without extensive modifications.

● Efficiency: Quick assembly and disassembly save time during setup.

DIY Projects and Custom Builds: For hobbyists and professionals alike, T-slot nuts simplify the creation of custom frames and structures. Whether you’re building a workstation or a display rack, they provide the adaptability needed for unique designs.

Here’s a quick overview of T-slot nuts in different applications:

Application Area | Use Case | Benefits |

Machining | Securing workpieces in milling | High precision and stability |

Woodworking | Assembling jigs and fixtures | Easy adjustments and reconfigurations |

Automation | Mounting in conveyor systems | Flexibility for changing layouts |

3D Printing | Frame and component mounting | Quick assembly and modifications |

T-slot nuts are not just fasteners; they are key components that enhance the functionality and adaptability of various systems. Their applications span across multiple industries, making them indispensable for both professional and DIY projects.

When it comes to fastening solutions, T-slot nuts and slotted nuts serve different purposes. Understanding their functionality helps you choose the right one for your project.

Detailed Comparison:

Feature | T-Slot Nuts | Slotted Nuts |

Design | T-shaped profile for sliding into slots | Flat design with external slots |

Locking Mechanism | Mechanical interlock within the slot | External locking with a wrench |

Adjustment | Easily adjustable for modular setups | Fixed once tightened |

Ideal Scenarios for Each Type:

● T-Slot Nuts: Best for applications requiring frequent adjustments. They excel in modular systems like frameworks in CNC machines or robotics.

● Slotted Nuts: Suitable for fixed connections in applications like automotive assemblies. Once secured, they provide a stable, permanent hold.

The mechanical interlock of T-slot nuts allows for a more secure fit in dynamic environments. In contrast, slotted nuts rely on external tightening, which can be less stable under vibration.

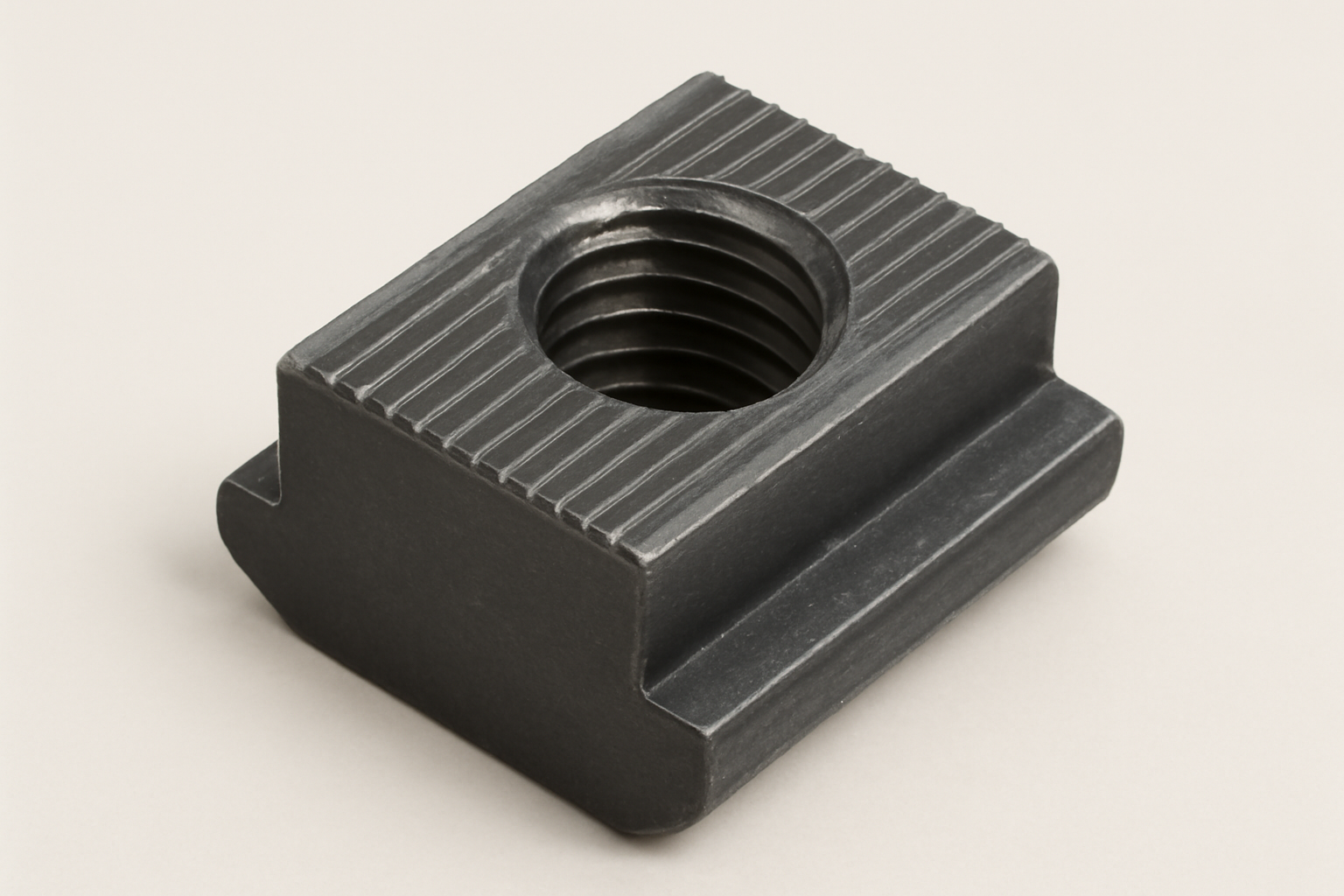

To better understand the distinctions, let’s look at the visual aspects of T-slot nuts and slotted nuts.

T-Slot Nut:

● Shape: T-shaped design fits snugly into T-slots.

● Usage: Ideal for adjustable frameworks.

Slotted Nut:

● Shape: Flat design with a slot for a wrench.

● Usage: Best for fixed, non-adjustable applications.

Design Features:

● T-Slot Nuts: The T-shape allows for easy insertion and adjustment within a slot, providing a strong mechanical grip.

● Slotted Nuts: The flat design allows for straightforward installation but lacks the flexibility of T-slot nuts.

By recognizing these differences, you can make informed decisions about which type of nut to use in your projects. Whether you need flexibility or stability, understanding their unique features is key.

In the world of fastening solutions, T-slot nuts are just one option. Let’s explore some alternative locking systems and how they stack up.

Overview of Locking Systems:

1. Self-Locking Nuts:

a. Description: These nuts have a nylon insert that grips the bolt.

b. Advantages: They resist loosening due to vibration, making them ideal for automotive applications.

c. Limitations: They can be expensive and may not work well in high-temperature environments.

2. Wedge-Locking Nuts:

a. Description: These nuts use a wedge mechanism to prevent loosening.

b. Advantages: They provide a strong hold and are reusable.

c. Limitations: Installation can be more complex compared to T-slot nuts.

3. Serrated Flange Nuts:

a. Description: These nuts feature serrations on the flange to grip the surface.

b. Applications: Commonly used in automotive and machinery applications where vibration is a concern.

Comparison Table:

Locking System | Advantages | Limitations |

Self-Locking Nuts | Vibration resistance | High cost, temperature sensitivity |

Wedge-Locking Nuts | Strong hold, reusable | Complex installation |

Serrated Flange Nuts | Good grip on surfaces | Limited adjustability |

The fastening industry is evolving rapidly. Here are some of the current trends influencing T-slot nuts and related products.

Current Trends:

● Sustainability: There's a growing demand for eco-friendly materials and manufacturing processes.

● Automation: Increased automation in manufacturing leads to a need for more reliable fastening solutions.

● Customization: More customers are looking for tailored solutions, including specific sizes and designs.

Innovations Related to T-Slot Nuts:

● Advanced Materials: New materials enhance strength and reduce weight, improving performance.

● Smart Fastening Solutions: Technologies like IoT are being integrated into fastening systems for better monitoring and control.

Potential Impact of New Technologies:

● Innovations could lead to T-slot nuts becoming more versatile and easier to use.

● The introduction of smart technology may facilitate real-time adjustments and monitoring, enhancing safety and efficiency.

These trends indicate a dynamic market where T-slot nuts and their competitors must adapt to stay relevant. Understanding these shifts helps manufacturers and users make informed choices about fastening solutions.

In industries like CNC machining, precision is everything. T-slot nuts excel in providing the accuracy needed for high-quality work.

Importance of Precision:

● CNC Machining: In this field, even slight misalignments can lead to significant errors. T-slot nuts help maintain tight tolerances.

● Stable Positioning: They fit snugly into T-slots, ensuring that components remain securely in place during operation.

Enhancing Workflow Efficiency:

● Adjustable Positioning: T-slot nuts allow for quick adjustments. This flexibility means operators can easily reposition components without losing stability.

● Visual Aid: Here’s how T-slot nuts improve workflow:

Feature | Benefit |

Quick Adjustments | Saves time during setups |

Secure Fit | Reduces downtime due to misalignment |

Versatility | Adapts to various applications |

When considering fastening solutions, cost is a major factor. T-slot nuts offer excellent value for money.

Standardization of Sizes:

● T-slot nuts come in standardized sizes, which simplifies inventory management. This standardization reduces costs associated with custom orders.

Long-Term Savings:

● Durability: T-slot nuts are built to last, meaning fewer replacements over time.

● Efficiency Gains: Improved workflow efficiency leads to lower labor costs.

Cost Comparison:

Fastening Solution | Initial Cost | Long-Term Cost Savings | Performance |

T-Slot Nuts | Moderate | High | Excellent |

Slotted Nuts | Low | Moderate | Good |

Self-Locking Nuts | High | Low | Variable |

In this comparison, T-slot nuts stand out for their balance of initial cost and long-term savings. They provide reliable performance, making them a smart choice for many applications.

With their precision, stability, and cost-effectiveness, T-slot nuts truly shine in the world of fastening solutions. Whether you're in manufacturing or assembly, these nuts are designed to meet your needs effectively.

Installing T-slot nuts is straightforward. Follow these steps to ensure a secure fit.

Step-by-Step Guide:

1. Prepare the T-Slot:

a. Clean the T-slot to remove any debris or dust.

b. Ensure the slot is free from obstructions.

2. Align the T-Slot Nut:

a. Insert the T-slot nut into the slot at an angle.

b. Rotate it until it aligns with the slot.

3. Secure the Nut:

a. Push down on the nut until it sits flat in the slot.

b. Use a wrench to tighten the bolt securely.

4. Check Positioning:

a. Ensure the nut is firmly in place and not loose.

b. Adjust as necessary before completing the assembly.

Common Mistakes to Avoid:

● Forcing the Nut: Don’t use excessive force when inserting. This can damage the nut or slot.

● Misalignment: Always check alignment before tightening. Misplaced nuts can lead to instability.

● Neglecting Cleanliness: Dust and debris can affect performance. Always clean the area before installation.

To keep your T-slot nuts in top condition, regular maintenance is key. Here are some tips to ensure longevity.

Tips for Maintaining T-Slot Nuts:

● Regular Inspections: Check nuts periodically for signs of wear or damage.

● Lubrication: Apply a light lubricant to the threads to prevent seizing and ensure smooth operation.

● Avoid Over-Tightening: This can cause unnecessary stress and wear.

Signs of Wear and When to Replace:

● Visible Damage: Cracks or deformities indicate it’s time for a replacement.

● Frequent Loosening: If nuts frequently come loose, they may not be functioning properly.

● Corrosion: Rust or corrosion can compromise the nut’s integrity.

Recommendations for Cleaning and Protection:

● Cleaning: Use a soft cloth and mild detergent to clean the nuts. Avoid abrasive materials.

● Protection Against Corrosion:

○ Store in a dry environment.

○ Consider using a protective coating or rust inhibitor if used in harsh conditions.

By following these installation and maintenance tips, you can ensure that your T-slot nuts perform reliably and last longer. They are a crucial component in many applications, so taking care of them pays off in the long run.

T-slot nuts play a vital role in many applications. Their precision and stability enhance workflow efficiency.

Consider using T-slot nuts for your future projects. They offer durability and cost-effectiveness.

Remember, T-slot nuts are a type of slotted nut. They provide unique advantages that can benefit your work.

A: T-slot nuts fit into T-slots for secure positioning, while slotted nuts have a simple slot design.

A: Yes, but choose corrosion-resistant materials for durability in harsh conditions.

A: Steel and aluminum are ideal due to their strength and resistance to deformation.

A: Most T-slot nuts are designed to fit standard T-slotted tables, but check specifications.

A: Measure the T-slot width and depth, then select a nut that matches those dimensions.