When it comes to selecting fasteners, choosing the right bolt is critical for the success and longevity of a project. Among the most widely used bolts, 304 stainless steel bolts stand out due to their impressive corrosion resistance and durability. Understanding what 304 bolts are, their properties, and how they compare with other types of stainless steel bolts can help ensure that you're choosing the right bolt for your specific needs.

In this article, we will dive into the characteristics of 304 stainless steel bolts, their uses across various industries, and why they are the preferred choice for many applications.

304 stainless steel bolts are made from an alloy composed of 18% chromium and 8% nickel. This combination makes the material resistant to corrosion, durable, and non-magnetic. As austenitic steel, it provides excellent resistance to oxidation and good strength at higher temperatures, making it suitable for a variety of environments. The addition of nickel ensures that the material remains ductile and easy to form, which is why it's commonly used in both manufacturing and structural applications.

304 stainless steel bolts are well-regarded for their excellent corrosion resistance, especially in non-marine environments where they may be exposed to moisture or corrosive chemicals. These bolts offer superior strength and durability, maintaining structural integrity over time. Their non-magnetic properties also make them suitable for specific applications where magnetic interference would be an issue, such as in certain scientific and medical devices. These bolts also provide good weldability, making them easier to work with during fabrication and installation.

Property | Description |

Corrosion Resistance | Excellent resistance to oxidation and rust. |

Tensile Strength | High strength for demanding applications. |

Durability | Long service life in harsh environments. |

Temperature Resistance | Can withstand high temperatures. |

Magnetic Properties | Non-magnetic nature useful in certain industries. |

304 stainless steel bolts are versatile fasteners used across various industries. In construction, these bolts secure structural components such as beams, columns, and frames. They are also commonly used in automotive applications, holding parts together in engines, fuel systems, and exhaust systems. Their ability to resist corrosion and perform well in high-temperature environments makes them ideal for industrial machinery, processing plants, and HVAC systems.

While 304 stainless steel offers excellent corrosion resistance, it is not as resistant to saltwater as other stainless steel grades like 316. However, it is still used in marine and coastal environments where the exposure to saltwater is moderate. For example, 304 bolts are used in the construction of boat trailers, fishing equipment, and structural elements in coastal infrastructure. While not suitable for direct immersion in seawater, they perform well in applications that experience occasional exposure to salt.

304 stainless steel is a popular choice in the food and pharmaceutical industries due to its non-reactive and easy-to-clean nature. These bolts are commonly used in food processing equipment, pharmaceutical machinery, and hygienic environments, where maintaining cleanliness and preventing contamination is critical. The corrosion-resistant properties of 304 stainless steel ensure that these bolts withstand the wear and tear of high-moisture environments without compromising hygiene standards.

Industry/Application | Key Use | Benefits of 304 Bolts |

Construction | Beams, columns, bridges | Corrosion resistance, strength |

Automotive | Engine components, exhaust systems | Durability, high temperature resistance |

Marine | Boat components, riggings | Saltwater resistance, durability |

Food Processing | Mixing, packaging machinery | Hygienic, corrosion-resistant |

Pharmaceutical | Bioreactors, equipment | Easy to clean, corrosion resistance |

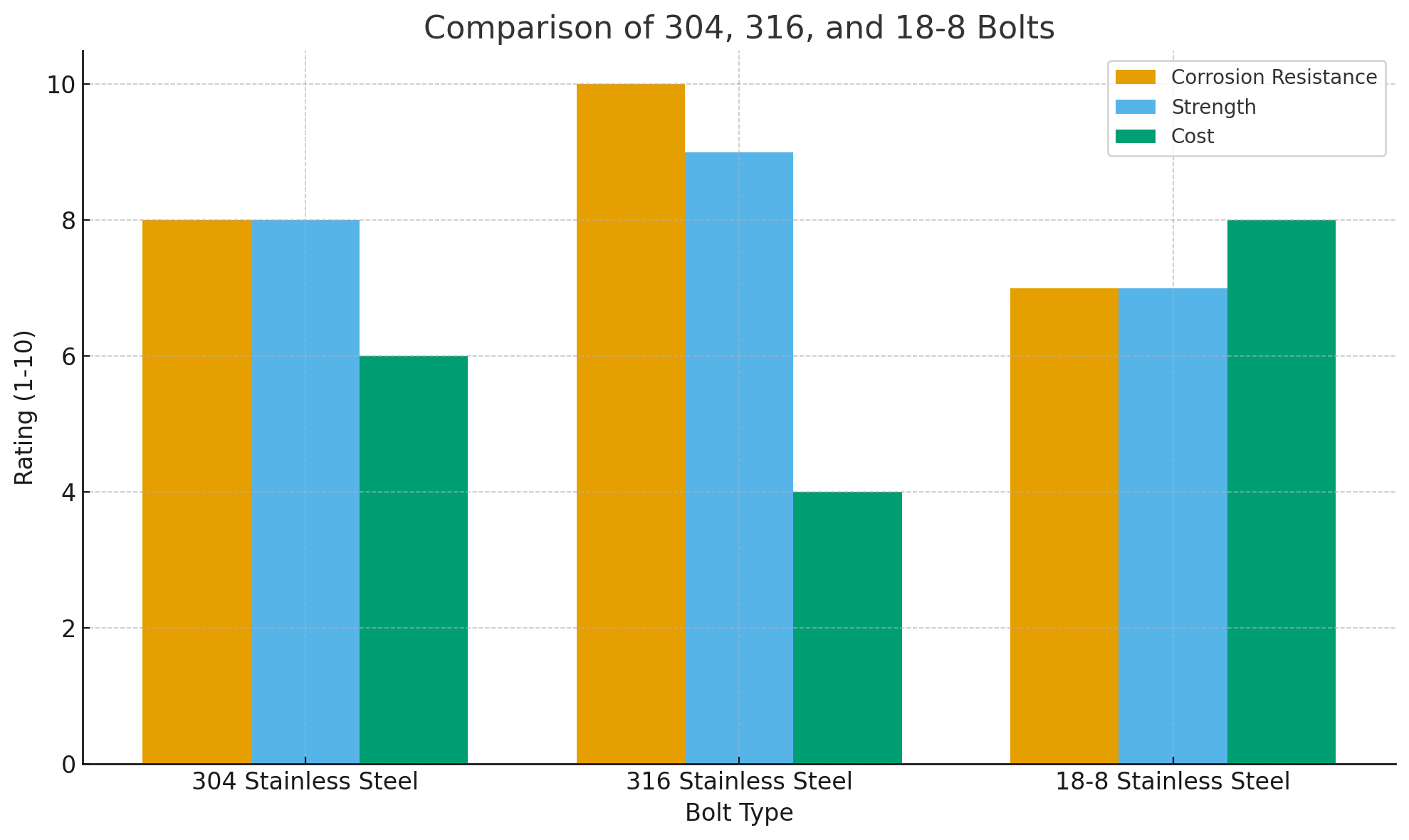

304 and 316 stainless steel bolts are often compared due to their similarities, but 316 offers enhanced corrosion resistance. The key difference lies in the addition of molybdenum in 316 stainless steel, which provides improved resistance to chlorides, making it more suitable for marine environments and applications exposed to harsh chemicals. On the other hand, 304 bolts are less expensive and provide sufficient protection for most general-purpose applications. When deciding between the two, consider the environment: 304 is ideal for industrial and construction applications, while 316 should be used in more corrosive or marine-based environments.

18-8 stainless steel is a subset of 304 stainless steel that contains 18% chromium and 8% nickel, similar to 304 bolts. However, 18-8 bolts are more commonly found in lighter-duty applications and offer lower corrosion resistance than 304 stainless steel. While both types are widely used in manufacturing and construction, 304 stainless steel offers better overall performance in terms of corrosion resistance and strength, especially in environments where exposure to chemicals or moisture is more significant.

Property | 304 Stainless Steel | 316 Stainless Steel | 18-8 Stainless Steel |

Corrosion Resistance | Good | Excellent | Moderate |

Cost | Affordable | Higher | Low |

Strength | High | Higher | Moderate |

Best Use | General applications | Harsh environments | General applications |

Key Components | 18% Chromium, 8% Nickel | 16% Chromium, 10% Nickel, 2% Molybdenum | 18% Chromium, 8% Nickel |

304 stainless steel bolts have a tensile strength of about 515 MPa and a yield strength of 205 MPa, making them strong enough to handle high stress without breaking. These bolts perform well in a variety of applications, providing reliable holding power in both structural and mechanical settings. Their ability to maintain strength under pressure makes them suitable for use in heavy-duty machinery, automotive components, and large-scale construction projects.

One of the defining features of 304 stainless steel bolts is their excellent resistance to corrosion, particularly in environments that involve exposure to air, water, and mild chemicals. While they may not withstand harsh chemical environments as well as 316 stainless steel, 304 bolts are ideal for environments like food processing or manufacturing facilities where moisture is prevalent. The formation of a protective oxide layer on the surface helps prevent rust and degradation, extending the lifespan of the fastener.

When selecting a 304 stainless steel bolt, it's essential to consider factors like the environment, temperature, and the type of load the bolt will bear. For example, if the bolt will be exposed to moisture or chemicals, 304 bolts are an excellent choice due to their corrosion resistance. However, for applications in highly corrosive environments, you may need to opt for 316 stainless steel or other specialized alloys. It's also important to consider the size and threading of the bolt, ensuring it fits the specific requirements of your project.

304 stainless steel bolts are commonly used in heavy-duty applications, but in extreme conditions, such as high temperatures or high-stress environments, other alloys like Grade 8 or titanium may be needed. If you're working on an industrial project that involves machinery, equipment, or structural components under significant strain, it's crucial to assess the tensile strength and the durability of the material used. For specialized lifting applications, triangle eye bolts made of 304 stainless steel provide additional strength and versatility, allowing for secure lifting operations while maintaining corrosion resistance.

Feature | Triangle Eye Bolt | Regular Eye Bolt |

Shape | Triangle shape for heavy lifting | Round shape for general use |

Strength | Higher tensile strength for lifting | Standard strength for light loads |

Best Application | Lifting heavy machinery, construction | General fastening or light lifting |

Material | Stainless steel, carbon steel | Stainless steel, carbon steel |

304 stainless steel bolts are known for their corrosion resistance, tensile strength, and durability, making them ideal for various industries. Whether in construction, automotive, or marine environments, these bolts deliver reliable performance. For projects requiring additional strength, triangle eye bolts provide the perfect solution, ensuring strength and reliability. At Ningbo Weifeng Fastener Co., Ltd., we offer high-quality fasteners tailored to meet the needs of your specific applications.

A: A 304 bolt is made from 304 stainless steel, which contains 18% chromium and 8% nickel. It offers excellent corrosion resistance and durability, making it suitable for various applications.

A: Triangle eye bolts are used in lifting and securing heavy loads. They provide a reliable solution in industries like construction and marine where additional strength is needed.

A: 304 bolts offer good corrosion resistance, but 316 bolts, with added molybdenum, provide superior protection against harsh environments, especially in marine applications.

A: Triangle eye bolts are designed for heavy lifting, offering superior strength and secure attachment, ideal for securing loads in construction or industrial settings.

A: Yes, 304 bolts are highly resistant to rust and corrosion, but they may not perform as well as 316 bolts in environments with high chloride exposure, like marine settings.

A: Yes, 304 bolts are commonly used in food processing industries due to their excellent corrosion resistance and hygienic properties.