Views: 0 Author: Site Editor Publish Time: 2025-12-03 Origin: Site

Bolts are essential in securing critical components across industries. Their strength determines the safety and durability of machinery and structures. Choosing the right bolt is crucial for reliable performance.

In this article, we will explore the strongest bolt types, materials, and their applications, including triangle eye bolts, and why selecting the right one matters for heavy-duty tasks.

Tensile strength is a critical factor in determining the strength of a bolt. It refers to the maximum stress a bolt can withstand before it breaks or deforms. When bolts are subjected to loads, tensile strength helps predict their ability to maintain the integrity of the connection. The higher the tensile strength, the greater the force the bolt can handle without failure.

In practical terms, a high tensile strength is essential when bolts are used to secure heavy machinery, infrastructure, or structural components that experience high levels of stress or pressure. The tensile strength is typically measured in megapascals (MPa) or pounds per square inch (psi), and it determines how well a bolt can withstand heavy-duty applications.

The strength of a bolt is influenced by various factors such as:

1. Material Composition: Different metals, alloys, and coatings affect the bolt's performance. For example, steel is commonly used for high-strength bolts, while alloys like titanium and stainless steel offer superior corrosion resistance.

2. Heat Treatment: Heat treatment processes like quenching and tempering can enhance a bolt's strength by altering the crystalline structure of the material.

3. Size and Threading: Larger bolts or bolts with deeper threads often have higher tensile strength. Thread design plays a role in distributing force evenly, minimizing stress concentrations.

4. Coatings and Surface Treatments: Coatings such as zinc or cadmium can improve corrosion resistance but may affect the bolt's overall strength, depending on the application and environment.

Understanding these factors helps in selecting the right bolt for specific applications, ensuring that the selected bolt can handle the required load and conditions.

Grade 8 bolts are among the most commonly used high-strength bolts. Made from medium-carbon steel, these bolts are heat-treated to achieve a tensile strength of 150,000 psi. This makes them suitable for demanding applications such as automotive suspensions, industrial machinery, and structural connections.

Grade 8 bolts are easily identifiable by six raised dashes on their heads. These bolts are ideal for applications that require a high degree of reliability and strength but do not require the extreme tensile strength of higher-grade bolts.

Grade 10.9 and Grade 12.9 bolts are made from high-strength carbon steel and have higher tensile strengths than Grade 8 bolts.

● Grade 10.9 Bolts: With a tensile strength of 1,040 MPa, Grade 10.9 bolts are often used in the automotive industry for engine components, transmissions, and other heavy-duty applications.

● Grade 12.9 Bolts: These bolts have a tensile strength of 1,220 MPa and are used in heavy-duty industrial machinery, aerospace, and high-stress applications where maximum strength is crucial. These bolts offer exceptional durability but are more expensive than lower-grade bolts.

Grade 14.9 bolts are the strongest bolts available, with a tensile strength of up to 1,400 MPa. These bolts are used in the construction and manufacturing industries for joining large structural elements such as beams and columns. Their extreme strength makes them suitable for applications where failure could result in catastrophic consequences. However, they are more brittle than lower-grade bolts and should be used with caution in dynamic applications.

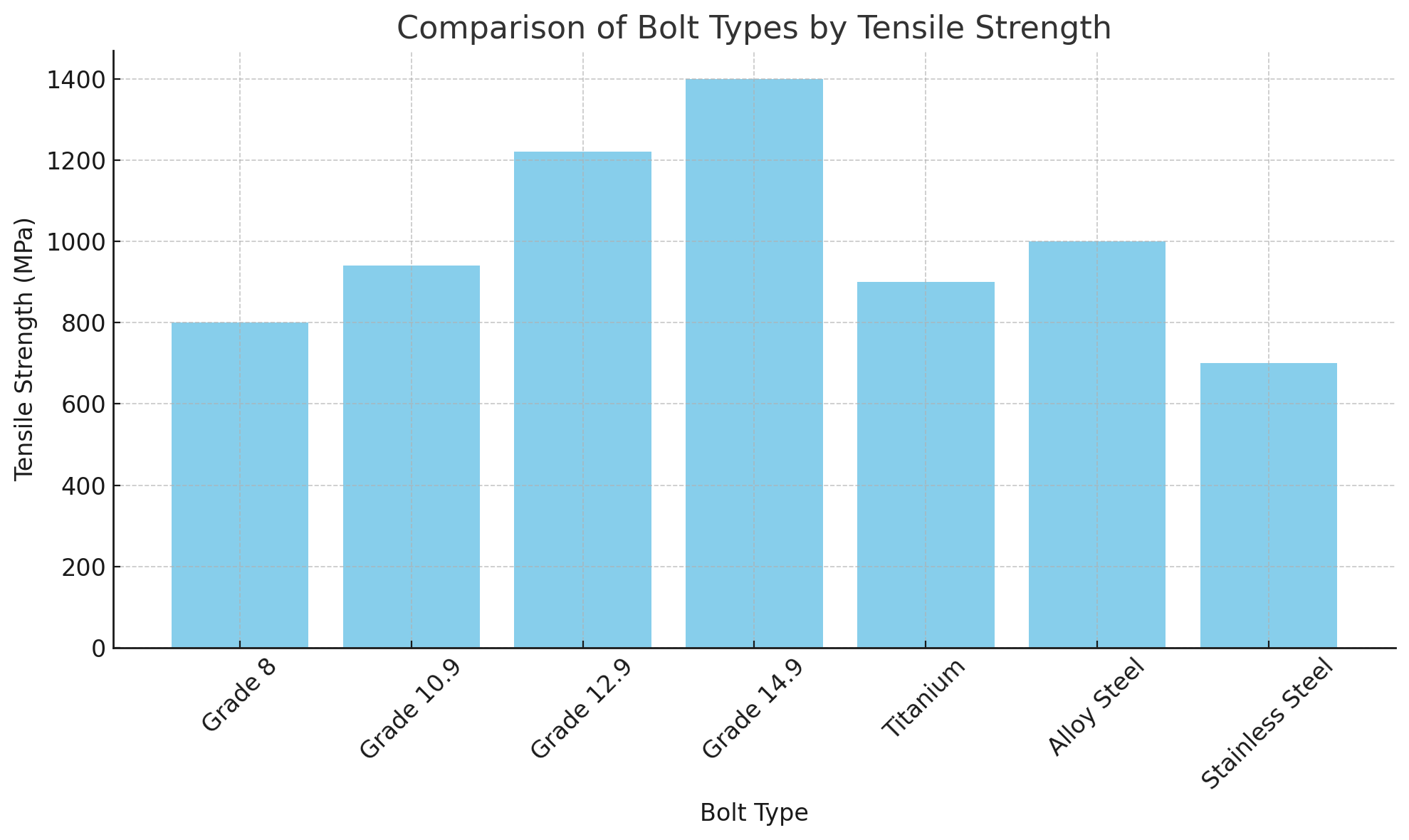

Bolt Grade | Tensile Strength (MPa) | Typical Applications |

Grade 8 | 800 | Heavy-duty machinery, automotive |

Grade 10.9 | 940 | Automotive, construction, industrial |

Grade 12.9 | 1220 | Manufacturing, heavy construction |

Grade 14.9 | 1400 | Structural steel, critical applications |

Titanium | 900 | Aerospace, marine, high strength-to-weight |

Alloy Steel | Varies | Industrial, high-stress applications |

Stainless Steel | 500-700 | Marine, food processing, corrosion-resistant |

Titanium bolts are known for their exceptional strength-to-weight ratio. These bolts are approximately 40% lighter than steel bolts, yet they are incredibly strong. Titanium bolts have a tensile strength of around 1,200 MPa, and their low weight makes them ideal for aerospace, marine, and high-performance automotive applications.

Additionally, titanium offers superior corrosion resistance, making it perfect for environments that are exposed to extreme temperatures or harsh chemicals. However, titanium bolts can be significantly more expensive than their steel counterparts, making them a specialty item.

Alloy steel bolts are crafted from a mixture of steel and other elements such as chromium, vanadium, and molybdenum. The inclusion of these elements significantly improves the strength, hardness, and wear resistance of the bolt.

● High-Strength Alloy Steel Bolts: These bolts can reach tensile strengths above 1,200 MPa and are used in heavy-duty industrial applications where high strength and durability are required. They are commonly found in machinery, structural steel, and aerospace components.

● Molybdenum-Alloy Bolts: These bolts are known for their resistance to high-temperature environments and are used in applications like gas turbines and chemical processing equipment.

Bolt Material | Strength | Corrosion Resistance | Best Applications |

Carbon Steel | High | Low | Construction, automotive, general machinery |

Alloy Steel | Very High | Moderate | Industrial machinery, structural components |

Titanium | High | Very High | Aerospace, marine, extreme temperature usage |

Stainless Steel | Moderate | Very High | Marine, food processing, outdoor environments |

Silicon Bronze | Moderate | Very High | Marine, electrical, corrosion-prone environments |

Stainless steel bolts offer a unique combination of strength and corrosion resistance. They are commonly used in marine, food processing, and outdoor applications where resistance to corrosion is more critical than the highest possible strength.

● 304 Stainless Steel Bolts: These are the most common type of stainless steel bolts, offering good tensile strength and corrosion resistance in fresh water and moderate environmental conditions.

● 316 Stainless Steel Bolts: These bolts are ideal for applications in marine environments and are more resistant to corrosion due to the added molybdenum in their composition. However, they have lower tensile strength compared to alloy steel bolts.

Each bolt type has its own strengths and weaknesses. Here is a comparison of the most common strong bolt types:

Bolt Type | Tensile Strength | Strength Characteristics | Common Applications |

Titanium Bolts | 1,200 MPa | High strength-to-weight ratio, corrosion resistance | Aerospace, marine, high-performance automotive |

Grade 8 Bolts | 150,000 psi | High strength, good for most industrial applications | Automotive suspensions, machinery |

Stainless Steel Bolts | 80,000 - 250,000 psi | Corrosion-resistant, lower strength compared to alloy steel | Marine, food processing, outdoor |

Grade 10.9 Bolts | 1,040 MPa | High strength, suitable for automotive and industrial machinery | Engine components, heavy-duty equipment |

While titanium bolts offer the best strength-to-weight ratio, they are not always the best choice for applications that require the highest tensile strength. Grade 8 and Grade 10.9 bolts provide excellent strength for most industrial uses, while stainless steel bolts excel in corrosion resistance.

When selecting a bolt, it is essential to consider factors such as the tensile strength required, environmental conditions, and the load-bearing capacity. For instance, if your application involves high temperatures and corrosion exposure, titanium or stainless steel bolts would be ideal. For heavy-duty structural applications, Grade 10.9 or Grade 12.9 bolts would be a better fit.

Always consult with a manufacturer or an engineer when selecting bolts for critical applications. Manufacturer specifications provide essential information on the strength, material properties, and usage guidelines of bolts, helping you make informed decisions. When using specialty bolts such as triangle eye bolts, it's important to follow the manufacturer’s guidelines to ensure they are used within the correct operational limits.

Bolt Type | Strength | Key Use Cases | Advantages |

Triangle Eye Bolt | High | Lifting, securing heavy loads | Precise, reliable, ideal for lifting |

Grade 8 | High | Heavy machinery, automotive | Strong, cost-effective for many applications |

Titanium | High | Aerospace, marine | High strength-to-weight ratio, corrosion-resistant |

Stainless Steel | Moderate to High | Marine, food processing | Corrosion-resistant, long-lasting |

The strongest bolts, such as Grade 14.9, titanium, and high-strength alloy bolts, are crucial for heavy-duty applications. Selecting the right bolt based on tensile strength, material properties, and project needs is essential. Bolts like triangle eye bolts provide superior strength, ensuring safety in lifting operations. For high strength and precision, triangle eye bolts are ideal, offering secure and reliable solutions. Ningbo Weifeng Fastener Co., Ltd. offers high-quality fasteners for various critical applications, ensuring lasting performance and safety.

A: The strongest bolts are typically Grade 14.9, titanium, and high-strength alloy bolts. These bolts are ideal for heavy-duty applications requiring maximum strength.

A: Triangle eye bolts offer exceptional strength, especially for securing heavy loads in lifting operations. They are often used when precision and durability are needed.

A: Grade 14.9 bolts have a high tensile strength of up to 1400 MPa, making them suitable for heavy construction and industrial applications where maximum strength is required.

A: Yes, triangle eye bolts are often used in marine environments due to their strength and reliability in securing loads, ensuring safety during lifting operations in challenging conditions.

A: Bolt strength depends on material composition, grade, heat treatment, and design. High-strength alloys, such as titanium and steel, enhance a bolt’s durability and performance.

A: Consider the tensile strength, material type, and application needs. For heavy lifting or critical operations, bolts like triangle eye bolts are an excellent choice for maximum security and strength.