Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

Eyebolts are vital in lifting and securing heavy loads, but not all angles are safe for use. Lifting at improper angles can lead to accidents or equipment failure. So, what angle is not recommended for eyebolts?

In this article, we’ll explore how angles impact the strength of eyebolts and the risks of lifting beyond safe limits. You’ll learn why triangle eye bolts and shoulder eyebolts are essential for safe angular lifting and how to avoid common mistakes.

An eyebolt consists of a threaded shank with a loop or "eye" at one end. The thread allows it to be securely attached to various materials such as wood, steel, or concrete. The primary purpose of an eyebolt is to serve as a lifting point for securing and hoisting loads. There are different types of eyebolts available, including plain eyebolts and shoulder eyebolts. Plain eyebolts are designed for vertical lifting only, whereas shoulder eyebolts are reinforced with a collar or shoulder, allowing them to handle angular loads.

Eyebolts are commonly used in a wide range of applications, particularly in construction, machinery, and marine settings. They are ideal for vertical lifts but can also be used in some angular lifting operations, depending on the type of eyebolt. In these scenarios, the right selection of the eyebolt type, size, and capacity is critical to prevent accidents. Furthermore, improper angle selection or incorrect use of an eyebolt can lead to equipment failure, compromising safety and causing potential damage to both the load and the equipment.

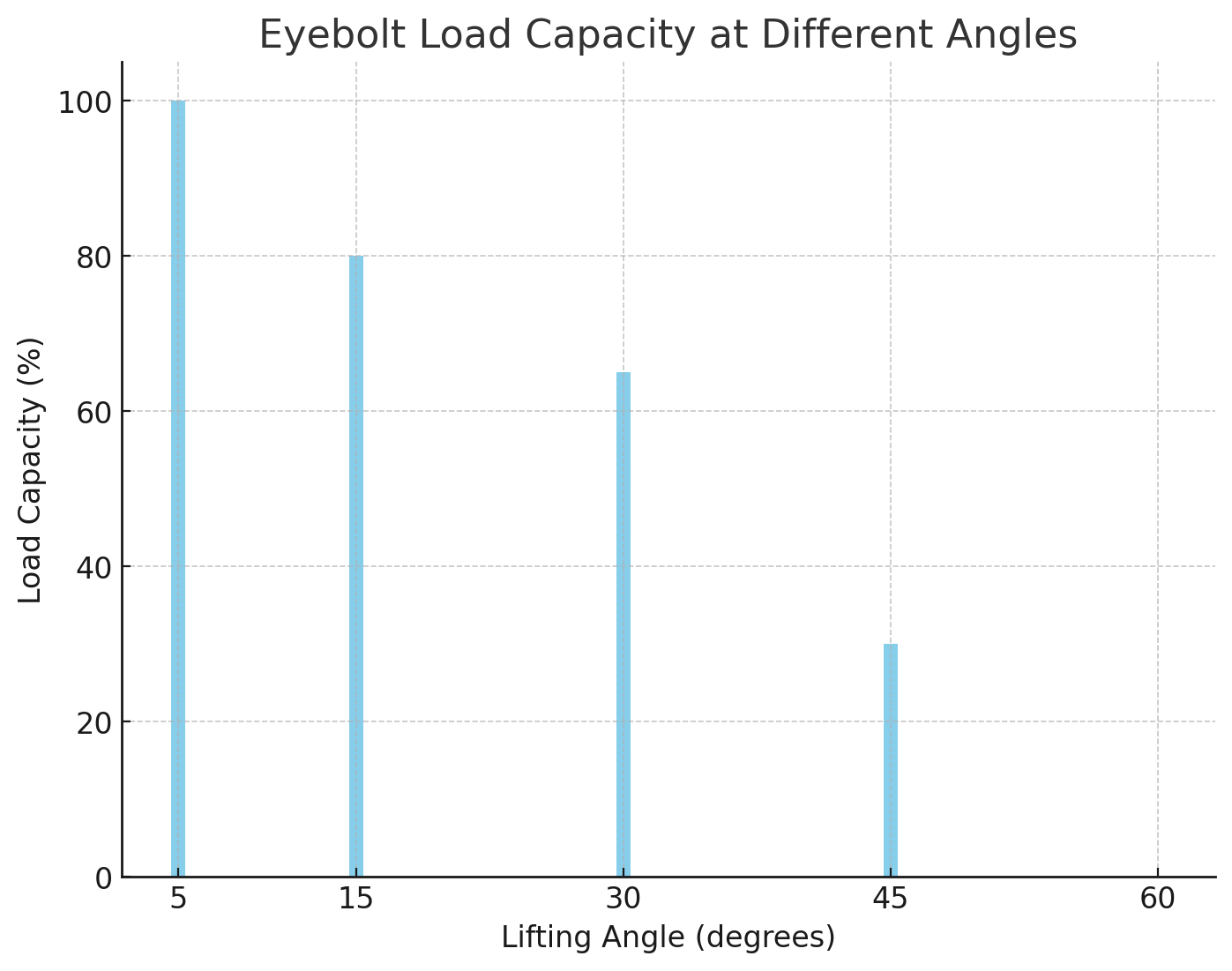

The angle at which a load is applied to an eyebolt has a significant effect on its load capacity. When lifting with an eyebolt at angles other than vertical, the load capacity of the eyebolt decreases. This reduction happens because the forces on the eyebolt become distributed in different directions, increasing the stress on the shank. For example, when lifting at a 45° angle, the strength of the eyebolt can be reduced to just 30% of its rated capacity. The greater the angle, the further the load capacity is diminished, making it essential to understand these limits when planning a lift.

The most critical angle to be mindful of is 45°. It is generally regarded as the maximum safe angle for lifting with eyebolts. Beyond this, the capacity significantly reduces, and the forces exerted on the eyebolt can become too much for it to handle safely. At 45°, the load capacity can be reduced to just 30% of the original vertical lifting strength. Understanding this is essential for maintaining safety during lifting operations. Ideally, lifting at an angle should be avoided whenever possible, especially when the load exceeds a certain weight or when lifting with smaller eyebolts.

Angle of Lift | Load Capacity (%) |

0° (Vertical) | 100% |

5° | 100% |

15° | 80% |

30° | 65% |

45° | 30% |

46°+ | Not recommended |

Lifting with an eyebolt at angles greater than 45° is highly discouraged. As the angle increases, the load capacity of the eyebolt decreases drastically. For instance, lifting at a 60° angle will reduce the capacity to just 20% of the original strength, and anything beyond that is considered unsafe. At this point, the load placed on the eyebolt exceeds its safe operational limit, which can result in the failure of the eyebolt, damage to the load, or even injuries. It is important to consult the manufacturer’s guidelines on load capacity at different angles to ensure safe operation.

As the angle of lifting increases, the tension on the eyebolt increases exponentially. For example, a load lifted at a 30° angle exerts a force that is about 1.5 times the weight of the load. At a 45° angle, this force increases even more. This added tension makes the eyebolt more susceptible to breaking, especially if the angle exceeds 45°. Eyebolts are designed to handle vertical lifts or lifts that are within a certain range of angles. Exceeding the safe lifting angles leads to an increased risk of failure and safety hazards.

There have been numerous incidents where eyebolts failed due to improper lifting angles. One common scenario is where workers use eyebolts at angles beyond 45°, causing them to snap under the weight. For example, in a construction site accident, an eyebolt was used to lift a heavy steel beam at a 60° angle. The increased tension on the eyebolt caused it to break, resulting in a dropped load and serious injury. These types of accidents underscore the importance of adhering to recommended lifting angles and using the correct type of eyebolt for angular lifts.

For safe angular lifting, it's essential to choose the correct type of eyebolt. Shoulder eyebolts are typically the best choice for angular lifts. These eyebolts are designed to handle side loads and are equipped with a shoulder that prevents excessive bending under tension. Plain eyebolts, on the other hand, should only be used for vertical lifting. If an angular lift is unavoidable, ensure that the shoulder eyebolt is properly seated and aligned to distribute the load evenly across the bolt.

Eyebolt Type | Suitable for Angular Lifting | Max Safe Angle | Notes |

Plain Eyebolt | No | 0° | Only for vertical lifts. |

Shoulder Eyebolt | Yes | 45° | Can handle angles up to 45°. |

Triangle Eyebolt | Yes | >45° (special case) | Better suited for angular lifts. |

For angles beyond 45°, it's recommended to use hoist rings instead of eyebolts. Hoist rings, such as the triangle eye bolt design, offer enhanced strength and flexibility, allowing them to handle extreme angles without the risk of losing capacity. These rings are designed to rotate and adjust to different lifting angles, making them a safer alternative for lifting loads at angles greater than 45°. Swivel hoist rings are also beneficial as they maintain full load capacity at all angles, unlike traditional eyebolts.

The material and construction of an eyebolt play a significant role in determining its load capacity and its ability to withstand different lifting angles. Alloy steel eyebolts are commonly used for high-capacity lifts, especially in colder environments, while stainless steel eyebolts are ideal for marine or corrosive environments. It's important to select the right material based on the conditions of the lifting operation, as different materials offer varying degrees of strength and angle tolerance.

The size of the eyebolt and the thread length also affect its capacity. Eyebolts with a larger diameter and longer threads tend to have a higher load capacity and are better suited for angular lifting. When using an eyebolt, ensure that the thread length is sufficient for the material being lifted, as inadequate thread engagement can lead to failure during lifting.

Material | Max Load Capacity | Suitable for Angles | Notes |

Alloy Steel | High | Up to 45° | Strong in extreme temperatures, high capacity |

Stainless Steel | Moderate | Up to 45° | Corrosion-resistant, good for marine use |

Carbon Steel | Moderate | 0°-30° | Not recommended for cold environments |

Before using an eyebolt, always perform a thorough inspection. Look for signs of wear, corrosion, or damage to the threads and eye. Any defect can weaken the eyebolt and compromise safety. Eyebolts should also be checked to ensure they are properly seated and aligned with the load.

To ensure the safety of your lift, proper installation of the eyebolt is crucial. Ensure that the eyebolt is securely threaded into the material and that the shoulder is flush against the surface. If necessary, use washers or spacers to align the eyebolt properly. It’s also important to make sure that the load is applied in line with the plane of the eye, as this will minimize the risk of bending or breaking.

If an eyebolt becomes overloaded, it’s essential to stop the lift immediately. Overloading can cause the eyebolt to fail, leading to the loss of the load or injury. In such cases, consider using a more robust lifting solution, such as a hoist ring, or reduce the angle of the lift to alleviate stress on the eyebolt.

Lifting with eyebolts at angles beyond 45° significantly reduces their load capacity and increases the risk of failure. It’s essential to stay within the rated capacity of the eyebolt. For safe angular lifting, use shoulder eyebolts or hoist rings. Ningbo Weifeng Fastener Co., Ltd. offers high-quality triangle eye bolts and swivel hoist rings that ensure greater safety and flexibility in challenging lifting scenarios. Always consult the manufacturer’s specifications and inspect your equipment regularly for safe operations.

A: The maximum safe angle for lifting with an eyebolt is 45°. Beyond this, the load capacity significantly decreases, risking failure.

A: Lifting at angles greater than 45° reduces the load capacity of the eyebolt to 30%, increasing the risk of equipment failure and accidents.

A: Yes, triangle eye bolts are designed to handle angular lifting more effectively than plain eyebolts, offering improved strength and safety.

A: Shoulder eyebolts are the best for lifting at angles under 45°, as they are designed to handle angular loads safely.

A: Lifting above 45° with an eyebolt compromises safety by drastically reducing its load capacity and increasing the chances of failure.