Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

Eyebolts are crucial for safe lifting and securing heavy loads. Their simple yet effective design makes them a go-to tool in many industries. However, a common question is: How much weight can an eyebolt hold?

In this article, we'll explore the factors that influence an eyebolt's weight capacity, including materials, design, and usage conditions. You'll also learn about the role of triangle eye bolts and how they perform in different scenarios.

An eyebolt consists of two main parts: a threaded shank and a loop or "eye." The threaded portion is designed to be inserted into a material (wood, metal, or concrete), while the eye serves as the attachment point for lifting or securing hardware, such as ropes, chains, or cables. The loop allows for a stable connection to the lifting equipment, providing a secure and reliable point for hoisting heavy loads.

There are different types of eyebolts based on their design and intended use. The two most common types are:

● Shoulder Eyebolt: This design features a shoulder that supports angular loads, allowing the eyebolt to handle forces applied at an angle. They are suitable for more dynamic lifting applications and offer better stability.

● Plain Eyebolt: These have no shoulder and are designed for vertical lifts only. They should never be used when loads are applied at angles, as this can lead to bending or breaking.

Eyebolts are used in various industries such as construction, marine, and manufacturing. They are most commonly found in:

● Construction: For lifting steel beams, concrete blocks, or other heavy building materials.

● Marine: Securing equipment or serving as a point for mooring boats and ships.

● Manufacturing: Used to lift heavy machinery parts or for securing equipment during transport.

Their primary purpose is to provide a secure, stable point for lifting, but they can also be used for anchoring and securing equipment in place.

Eyebolt Type | Best Use | Advantages |

Shoulder Eyebolt | Angular lifting | Handles angled loads better, more stable |

Plain Eyebolt | Vertical lifting only | Simpler design, cost-effective |

Triangle Eye Bolt | Heavy-duty, dynamic loads | Stronger load distribution, more stable |

The Working Load Limit (WLL) is the maximum weight an eyebolt can safely handle under normal lifting conditions. It’s typically marked on the eyebolt itself, and it is crucial to never exceed this limit. WLL is calculated by the manufacturer based on the material, size, and design of the eyebolt.

For instance, a small steel eyebolt with a ¼-inch shank may have a WLL of 600 pounds in a straight-line lift. However, at an angle, this capacity could be reduced, so it’s essential to always check the manufacturer’s specifications for the correct WLL.

The weight an eyebolt can hold is influenced by several factors:

● Material: The material of the eyebolt significantly affects its strength. Eyebolts made of stainless steel are highly resistant to corrosion and can withstand higher loads in harsh environments, while carbon steel eyebolts are suitable for most standard lifting applications.

● Shank Diameter and Length: Larger diameters offer greater strength, which means the eyebolt can hold more weight. For example, a 1-inch diameter eyebolt can carry significantly more weight than a ¼-inch version.

● Design: The presence of a shoulder on the eyebolt affects its strength. Shoulder eyebolts are ideal for angled lifts, while plain eyebolts are strictly for vertical lifts.

Material | Advantages | Ideal Use |

Stainless Steel | Corrosion-resistant, durable | Marine, outdoor use |

Carbon Steel | Strong, affordable | General lifting tasks |

Alloy Steel | High tensile strength, durable | Heavy-duty industrial lifting |

The shank diameter is one of the primary determinants of an eyebolt's weight capacity. As the diameter increases, so does the eyebolt's ability to handle heavier loads. A ¼-inch shank might support around 600 pounds, while a 1-inch shank could easily support 10,000 pounds or more, depending on the material and design.

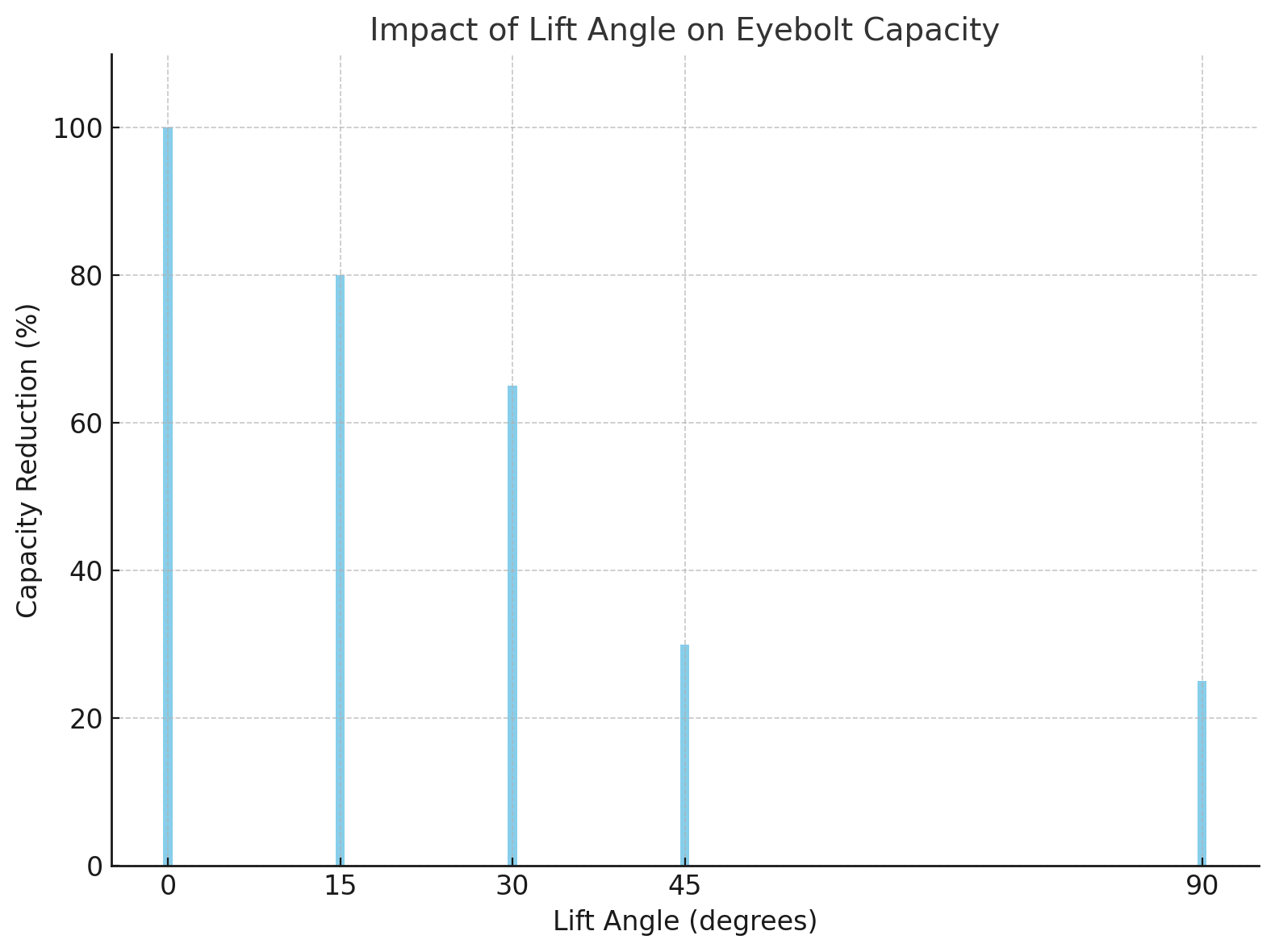

When lifting a load at an angle, the weight capacity of an eyebolt decreases. This is because the force is applied differently compared to a vertical lift. For example, at 5 degrees, the weight capacity remains at 100%. But at 15 degrees, the capacity drops by 20%, and at 30 degrees, it’s reduced by 35%. By the time you reach 45 degrees, the capacity could decrease by up to 70%.

It’s important to note that shoulder eyebolts are designed to handle some degree of angular loading. However, beyond a certain angle, the load should be shifted to alternative lifting methods, like hoist rings, to ensure safety.

Cold weather can also affect the strength of an eyebolt, particularly for carbon steel models. At temperatures below 30°F (-1°C), steel can become brittle and lose its strength. Always ensure that the material and specifications of the eyebolt match the environmental conditions where it will be used. Stainless steel and galvanized steel are more resistant to corrosion and temperature variations, making them ideal for outdoor and marine environments.

Shoulder eyebolts are specifically designed to handle angular loads. They are typically rated to hold heavier weights than plain eyebolts when used at angles, thanks to the shoulder that prevents the shank from bending under stress. These eyebolts can handle both vertical and angular lifts, but it's important to follow the manufacturer’s guidance on maximum angle limits.

Plain eyebolts, as the name suggests, have no shoulder and are intended for vertical lifting only. They are often used in applications where the load will be lifted straight up and down, like in construction when hoisting materials like steel beams. The WLL of plain eyebolts is typically lower than shoulder eyebolts, and any sideways force can cause the bolt to bend or fail.

One specific variation of an eyebolt is the triangle eye bolt. These eyebolts are typically used in applications requiring a more robust connection, such as in rigging or construction projects. The triangle eye provides better load distribution and greater stability when securing or lifting a load.

● Triangle eye bolts are particularly suited for environments where traditional eyebolts might struggle with stability or where load distribution is a concern. These eyebolts are designed to distribute weight more evenly, making them ideal for heavier loads and more demanding tasks.

Before using any eyebolt, it is essential to inspect it for signs of damage. Look for cracks, rust, or deformation in the eye and shank. Even small nicks can compromise the integrity of the eyebolt and reduce its weight capacity. Always ensure the WLL is clearly marked and visible before use.

Eyebolts must be properly installed to ensure that they perform at their maximum capacity. When installing an eyebolt, ensure that the shank is properly threaded into the material, and the nut (if applicable) is tightened securely. If the bolt is not seated properly, it can shift or even fail during lifting.

Overloading an eyebolt is one of the most common causes of failure. Never exceed the WLL of any eyebolt, and always factor in the angle of the lift. If your lift requires more weight capacity, consider using a hoist ring or increasing the number of eyebolts used.

Choosing the right eyebolt depends on your lifting application. For vertical lifts, plain eyebolts are sufficient. However, for angular lifts, shoulder or triangle eyebolts are ideal. Consider the size of the load, the angle of the lift, and the material of the eyebolt when making your selection.

Always refer to the manufacturer's technical datasheet or WLL chart when selecting an eyebolt. This will help ensure you are using the right size and type of eyebolt for your specific lifting needs. Manufacturers will provide detailed specifications that include not just the WLL, but also installation guidelines and the max safe angle for load application.

Eyebolts are crucial for lifting and securing heavy loads. Understanding the working load limit (WLL), installation techniques, and capacity factors ensures safe operations. Whether using triangle eye bolts, shoulder eyebolts, or plain eyebolts, selecting the right type is essential. Always check the WLL to avoid accidents. At Ningbo Weifeng Fastener Co., Ltd., we offer high-quality fasteners designed to enhance safety and performance in every lifting task. Our products provide reliable solutions tailored to your needs.

A: The weight capacity of an eyebolt depends on its size, material, and design. Generally, eyebolts are rated with a working load limit (WLL), which varies by type. A triangle eye bolt typically has a higher weight capacity due to its robust design and efficient load distribution.

A: A triangle eye bolt is commonly used for heavy-duty lifting and securing, offering a stronger and more stable attachment point compared to traditional eyebolts. Its triangular shape helps in load distribution, making it ideal for demanding applications.

A: To choose the correct eyebolt, consider the weight of the load, the type of lift (vertical or angular), and the eyebolt's working load limit (WLL). A triangle eye bolt is a good option for heavier or more dynamic loads due to its unique design.

A: Yes, lifting at an angle reduces an eyebolt's weight capacity. For example, a triangle eye bolt can handle angles better than plain eyebolts, but exceeding certain angles may still lead to a reduction in capacity.

A: Checking the WLL ensures that the eyebolt can safely support the load. Overloading an eyebolt can result in failure, risking damage or injury. Always consult the manufacturer's specifications for triangle eye bolt WLL ratings to maintain safety.

A: Shoulder eyebolts are designed to handle angular loads, while plain eyebolts are only suitable for vertical lifts. A triangle eye bolt, with its reinforced design, can offer advantages over both in terms of stability and weight capacity.